Utilizing three-tier architecture to lower total cost of ownership (TCO) in Manufacturing Execution Systems (MES)

Contents

• Thin technology defined

• Industry evolution

• Three-tier system architecture

• Thin technology initiatives lower total cost of ownership

• Interoperability between platforms

• Benefits of three-tier architecture

• The future of MES

Manufacturing Execution Systems (MES) are a key component in the globally competitive manufacturing environment. In this new millennium, with visualization of the supply chain and e-commerce, more manufacturers are pushed towards build-to-order and visualized manufacturing management in order to remain competitive. As MES has primarily been a tool for real-time manufacturing operations management, MES are evolving into the enabling technology for supply chain maintenance and e-commerce, affording operations visibility, real-time inventory status and dynamic manufacturing responsiveness. These industry pressures have led manufacturers to need to implement applications across multiple platforms, making such applications much more difficult to maintain. The high cost of system maintenance has led the manufacturing industry to evolve technology into a "thinner" system design.

Classically, maintenance costs incurred 80 percent of the five-year total cost of ownership of Information Technology (IT)-based systems. Today's technical objectives are to overcome industry pressures that would cause more expensive systems, from a maintenance perspective, and to utilize technology that will, in fact, result in a "thinner" (less expensive to maintain) solution. Regardless of the complexities and frequency of configuration changes (a design that reduces ERP connections from many connections to one connection), three-tier architecture requires very little maintenance, which lowers the total cost of ownership. Three-tier architecture offers improved scalability and manageability because changes in one tier are transparent to the other tiers. Development of the three-tier system is faster, and the system itself becomes a strategic, flexible tool with infinite possibilities to extend information and resources to more platforms at a lower cost than ever before.

Back to top

Thin technology defined

A thin technology (hardware or software) is one that eliminates points of maintenance. Windows Terminal Server technology actually uses a combination of hardware and software to achieve its thin Windows Terminal deployment. By providing the Windows applications via an application server, the Windows Terminal does not have application software requirements. Therefore, a much less expensive terminal can be used to access Windows applications. The "thin" effect occurs when Windows applications are maintained and upgraded at the server rather than at each client, thus greatly reducing the number of points of required application maintenance. This same analogy applies to the software maintenance requirements for object broker, object-based transaction middleware, Internet application, wireless application and multi-platform application interoperability technologies.

Back to top

Industry evolution

Although three-tier applications have become mainstream technology over the past few years, it is important to understand why this has happened and what has influenced the manufacturing industry. Industry movements that have influenced MES technology include: the Internet and e-commerce, a downsized IT workforce, system integrator technology challenges, supply chain visibility and scalability factors. In addition to understanding how these industry movements became technology pressures, it is important to understand how to best utilize current technology in ways that will benefit any manufacturing facility, including the benefit of lower total cost of ownership.

Internet and e-commerce

Global adoption of the Internet as the preferred medium for business communications has led to a growing demand for "Web-enabling" solutions. A Web-enabling solution is one that provides a client with Web-based access to existing, non Web-based applications. The ability to publish existing applications to the Web, thus eliminating the need to purchase and/or develop new Web-based applications, has tremendous appeal to today's IT decision makers in the manufacturing environment.

Internet applications employ multi-tier architecture. For Internet applications, logic must be deployed on the middle tier, sometimes called the business objects layer. This multi-tier architecture is not limited to Internet applications and, in fact, is a key element providing greatly decreased maintenance and lower total cost of ownership of MES .

Intranet browser access

The intranet (Internet technology contained within a company — no access from outside the company) is quickly becoming the platform of choice for administrative, support and management access to manufacturing operations data. IT departments embrace this approach because it provides a zero-maintenance client (Web browser). The multi-tier architecture removes all application-specific software from the client and creates a client that does not have any application specific software. Therefore, there is no application specific software to maintain. When IT departments are supporting hundreds to thousands of users, this approach to reduced client support/maintenance is quite significant.

Downsized it workforce

Although MES continues to grow in scope and complexity, end-users seem inclined to devote fewer in-house resources to development and maintenance. Many manufacturers have eliminated their staff IT positions entirely, preferring to hire the help they need when they need it, on a short term (project) basis, or via longer term outsourcing deals. This trend in manufacturing IT workforce reduction further reinforces initiatives to produce systems that are easier to maintain.

System integrator technology challenge

As manufacturers outsource more engineering/IT work, the system integration business has grown dramatically. The system integration marketplace is constantly expanding its service offerings in order to put all the pieces together to serve the needs of clients in the industrial environment. The growing trend towards outsourcing is occurring because process managers look to outsource tasks that they do not consider among their core competencies and/or because immediate resource demands of deploying new applications greatly exceeds the resource requirements to maintain those applications. Choosing not to outsource often leads to a negation of any return on investment and systems without the latest possible MES technology or functionality.

In the world of ever-changing technology and global competition where system integrators are everywhere and described in multiple ways, it is difficult for a manager to differentiate between them to find the skills and support they need. System integrators are trying to supply the technical edge that their clients lack at the lower costs that their clients need. In addition to expertise and experience, the key to being successful in this evolving industry is to build relationships with clients by becoming a reliable source of service offerings and technology, while maintaining cost-effective solutions. Reliability means keeping up with today's rapid advancements in MES solutions in order to provide the client with full functionality and the benefits of a complete solution.

Today's system integrator cannot afford to focus on proprietary-technology based solutions. Proprietary-technology training creates specialists that are either locked into a single vendor support role or heavily invested in training and poorly utilized for that investment. Collaborative developers spend significant effort integrating parallel development in large projects using classic system design. By adopting a widely accepted object-based transaction middleware technology, system integrators can establish a base level of training that can apply to any vendor or project utilizing the same architecture, which also benefits the system integrator by vastly reducing parallel development integration requirements.

Supply chain management

Integrating manufacturing systems is a relatively new direction for companies to look towards to improve supply chain management. Manufacturers optimizing the supply chain require good information about their operations. In fact, most of the information used in plant decision-making comes from the plant floor itself, regardless of the timeliness and accuracy of that data.

The central role of manufacturing in the supply chain has led many companies to justify plant-to-enterprise integration initiatives on a strategic basis. In fact, improved supply chain visibility — timely, accurate data about raw material requirements and consumption, production orders and schedules, etc. — is one of the top reasons that drives companies to make this change. Companies choose to implement MES because of a need to consolidate data into a single system, which enables more consistent decision-making and reduces the amount of required interfacing.

Scalability

One of the driving factors that led multi-tier applications to the mainstream is scalability. Scalability requirements of the manufacturing environment mean that the system architecture has to service an ever-increasing number of requests from clients. Two-tier client-server applications do not economically scale well. Developers begin to run out of memory and resources. Therefore, technology is needed to support on-demand concurrency.

Object-based transaction middleware that is aware and integrated with an object-broker is the technology that allows MES applications to be truly scalable, both in capacity and across the manufacturing enterprise. This technology makes it possible to use clusters of low-cost hardware and existing software to build scalable Internet and multi-tier client-server applications. The design of object-based transaction middleware, including its software automation and system integration, is providing companies with a compelling reason to build Windows-based MES applications through three-tier architecture in order to lower their total cost of ownership. The object –based transaction middleware will also make it easier for cross-platform developers to build effective gateways between the Windows environment and the rest of the operating-system universe.

Back to top

Three-tier system architecture

One of the key elements of any application design is the system architecture. The system architecture defines how pieces of the application interact with each other and what functionality each is responsible for performing. A recent advance in client/server development is the three-tier architecture design. Traditional client/server applications are two-tier, consisting of a client and a server. This can potentially lead to problems of a "fat client" or "fat server" if too much work is concentrated in either the client or the server, thus increasing maintenance and cost of ownership.

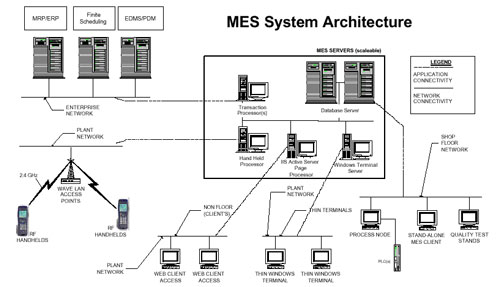

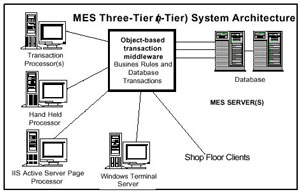

The three-tier architecture introduces a middle layer, which serves to ease the processing burden of the other two ends. Designed in several logical layers or tiers, these tiers do not necessarily correspond to physical locations on various computers on a network, but rather logical layers of the application. Three-tier architectures are comprised of clients, application servers and databases. Clients at tier one provide the user interface and some amount of the application's logic. This tier gives a user access to the application by presenting data to the user and optionally permitting data manipulation and/or data entry. There are three main clients or platforms of user interface for this tier: plant-floor PCs, Web-based browsers, and wireless hand-held units. The later two clients use thin client technology.

Web-based applications have recently evolved to contain most of the data manipulation features that traditional applications use. One key advantage is that anyone who has a browser client can access the MES applications. Standard Web browsers provide all of the required client functionality. Web clients have greatly eased management because an update to the Web server automatically updates all clients. Managing Web page code at a few servers is easier than managing application versions at many clients.

Application servers at the middle tier, consisting of data validations and enforcement of business and data rules, implement most of the business services. For example, this tier might simply open a database connection, invoke SQL queries and return results to the clients. Or, the server may house more complex rules, as in the classic manufacturing example: inventory movement – when inventory is moved from one location to another – subtract inventory from the starting location and add it to the destination location. Both of these actions need to be rolled into a single transaction. If either fail they both roll back. All of these business rules need to be built into the application server of the middle tier. Therefore, you just have to modify or replace the middle tier if the business rules ever change. There is no need to migrate the changes to the user-client (tier one) or database tiers (tier three).

The application server runs under the control of the object-based transaction middleware. Since the server is not tied to a specific client, it can be used by all various platforms of clients to assist in sharing resources and information. The middle tier must be easily accessible to all clients so that they are able to talk to it.

The database at the back end (tier three) provides persistent data storage, consisting of both the data and the means of accessing and maintaining it. Data is accessed through the application server and, on occasion, directly by the clients (browser, plant-floor and wireless platforms). Back office functions, including Database Administration, can also access tier three directly.

Back to top

Thin technology initiatives lower total cost of ownership

Currently, very few manufacturing environments have plant floors that operate on Internet technology. Rather, they operate on proprietary and client-server technologies. Many IT managers at these manufacturing plants have begun to evaluate solutions to integrate the plant environment with the company's business environment. Corporate planners have discovered that real-time visibility into plant information and actual plant performance is necessary in achieving maximum benefits from supply chain planning and ERP (Enterprise Resource Planning) applications.

With the growing trend in the competitive environment to be proactive to change, a company must strategically choose its MES if it wants to lower the total cost of ownership. The many applications of the MES solution must fit within an integrated architecture that allows for agility and as-needed reconfiguration. The three-tier architecture is helpful for successful integration of plant-floor systems with business systems. The three-tier architecture allows companies to gain a competitive advantage through the system design by reducing the cost of non-production activities, such as engineering changes, that tend to increase ownership expenses.

All too often, companies that choose to replace or enhance current systems do not get the technology that they really need and their costs go up rather than down. Most currently built MES result in systems echoing the same cost of implementation and ownership as the existing systems. Adding to the cost of deployment, MES has traditionally required significant customized integration to accomplish bi-directional communication between plant-floor control systems and business systems.

If the MES does not utilize thin technology, the largest cost is felt when change occurs within the manufacturing environment. The result becomes a continuous investment, negating any return on investment or reduction in total cost of ownership. The MES requiring maintenance in multiple locations across both business and plant-floor systems extensively multiplies the time and costs of changes to the system, versus the reduced time and costs of changes at the MES level of a thin system design. Thin technology drastically reduces the total cost of ownership because objects are pooled to a central location and applications are maintained at a single point rather than across a network of individual computers requiring individual maintenance. The thinner the design, the less maintenance and cost the manufacturer incurs.

By itself, technology does not save money. Technology, however, should not be a barrier to implementation. Rather, technology should be the backbone for developing a robust, scalable system. A key measure of a system's success is how much time is spent on maintenance. In order to keep costs lower, the MES cannot be an impediment to change. It must reconfigure and adapt to the dynamic manufacturing environment without shutdowns and changes in company planning.

Since historically the total cost of ownership is heavily weighted around the maintenance of a project after its deployment, system integrators implement object and thin technology to significantly reduce the cost of maintaining applications. An integrator can also design the MES applications to comply with the transaction middleware and as a result, those applications can be supported on three platforms of deployment (floor, wireless and browser clients) by a single, common set of middleware objects.

Utilizing widely accepted object-based transaction middleware technologies makes application code and deployment much easier and less costly to maintain because the MES business logic and database transactions are maintained at one central location. This single point of maintenance is the greatest benefit of this application design. It means a significantly reduced cost for maintaining multiple applications on multiple levels of data accessibility (floor, wireless, and browser clients) for the end users.

Back to top

Interoperability between platforms

One of the biggest challenges an IT department faces is trying to maintain identical functionalities for an application that appears on multiple platforms. Classically, there is a separate application and version for each platform. Whenever MES software was updated, programmers were forced to trek from platform to platform and sequentially upgrade each platform. IT personnel rarely have enough bandwidth or time to do them all at once. As MES became more complex and capable, maintenance became more complex, which increased the total cost of ownership.

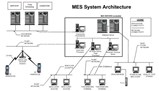

Probably the largest single benefit of using object-based transaction middleware technologies is the ability to develop one set of objects and employ them against several compliant platforms. These figures showing the system architecture detail how the classical MES architecture could have at least four different platforms. Through object-based transaction middleware, developers reduce the database transactions and business logic to a common set of objects for all platforms of application deployment. Developers can modify that single set of objects to maintain the applications across all four of those platforms. This simplification of application maintenance allows for increased interoperability between platforms and an overall cost reduction.

Back to top

Benefits of three-tier architecture

While several methods and technologies have been discussed, each having its own benefits, little has been reviewed that implies these technologies can be combined. In fact, the benefits accumulate as these technologies are integrated into a single architecture. The following lists the different technologies and reviews the benefits they contribute to the overall design.

Core architectural technology

Object broker and distributed object services

This provides connectivity in the transaction middleware environment and defines the interfaces and protocols for communication within and between application components. Little connectivity programming is required in this environment because many of the services that developers manually configure are part of the operating system. In large applications, where programmers develop concurrently on the same application, object technology virtually eliminates the internal integration typically required in parallel development projects. Object technology reduces time, effort and complexity of application development, deployment and maintenance. Thus, greatly decreasing costs.

Transaction layer n-Tier Architecture

This addresses a broad range of requirements in developing and deploying three-tier applications. While object broker technologies provide significant technological advances, they still require deployment on the client network. Transaction middleware technology allows object technology to migrate to a server-side NT service. This greatly reduces the points of maintenance for the application objects and makes the resulting applications much less expensive to maintain.

Transaction middleware increases overall application performance because it manages components and handles transactions, providing a transaction support property for each component installed within it. Transaction middleware pools and shares database connections the same way it does components, which reduces the load on the server. By reducing the points of maintenance, the application maintenance is simplified.

This technology also frees developers to focus on solving business problems because it is designed to simplify the development of the middle tier by providing much of the infrastructure needed to execute the business logic that runs there.

Thin application technology

Internet applications/browser clients

Both users and IT Departments embrace this technology, wanting plant-floor applications and data available via Internet applications. The browser-based application does not have an application to maintain on the client. All application maintenance is performed on the web server. The benefit of Internet-based applications is found in maintaining the application. By reducing the points of maintenance, the application maintenance is simplified. Using the three-tier architecture, the host application is responsible for the user interface and communication to its clients, while the object-based transaction middleware objects provide the database transactions and business logic.

Windows Terminal Server

Three-tier architecture can also use thin-client/terminal technology on its first tier in the form of a remotely cast user interface. A commercial example is Windows Terminal Server (WTS). Designed for the plant floor, the remote user interface provides similar benefits as Internet Applications with the additional benefit of reduced hardware requirements. Between Internet and remote user interface technologies, the primary difference is that the applications for a remote user interface are simply non-Internet applications. The host provides the application and the client (thin terminal) views the application. All application maintenance is performed on the host. Using the three-tier architecture, the host application is responsible for the user interface and communication to its clients, while the object-based transaction middleware objects provide the database transactions and business logic. The greatest benefit of a remotely cast user interface is the single point of application maintenance.

Wireless Computer Clients

Classically, in order to be functional each hand-held terminal had to be programmed to interpret each command from its keypad and communicate with a proprietary controller. Now, most wireless terminal technologies support TCP/IP, Telnet Services and VT100 emulation. New versions are emerging that support Windows CE. Using these technologies, the wireless system architecture can follow the thin systems architecture technology. Using the three-tier architecture, the host application is responsible for the user interface and communication to its clients, while the object-based transaction middleware objects provide the database transactions and business logic. The greatest benefit of this wireless systems architecture is the single point of application maintenance.

Platform interoperability

Object broker and object-based transaction middleware technologies for Manufacturing have profoundly altered the landscape of technology for developers by providing them with a model to design and develop robust, scalable, multi-tier, distributed applications. Many manufacturing sites have the opportunity to employ MES applications that utilize Internet, Intranet, Windows Terminal Server, wireless handheld barcode scanners, shop floor applications and back office IT business integration applications all within (not just the same site) the same project. The significance and magnitude of utilizing one single set of transaction middleware objects across all these platforms is immense.

Classically, IT departments would sequentially upgrade/modify each platform. By the time they completed the circuit, it would be time to start the next upgrade. It was a tremendous challenge for both the user community to determine which platform had up-to-date functionality and the IT department to keep changes identical as the rollout continued.

Three-tier architected applications provide an outstanding cost/performance ratio and a low total cost of ownership. The three-tier architecture builds on what developers know today and adds features that developers can leverage for enhanced scalability and reliability. Leveraging all technologies into an accumulated effect produces the largest benefit. Many leading manufacturing companies that have implemented the three-tier architecture have begun to realize these significant benefits.

Back to top

The future of MES

Manufacturing Execution Systems are built on the foundation of services provided by the Windows NT operating system and its compatibility with object-based transaction middleware. The architecture is object-oriented, three-tiered and distributed technologies. These technologies should be built upon through the utilization of thin clients and thin technology to deliver a tailored MES approach to solving business problems.

To meet the challenge of a competitive global economy while continuously reducing inventory and labor costs, manufacturing companies are increasingly relying on a new generation of MES technologies to help them meet this goal. The object-based transaction middleware provides a platform for building MES applications that will evolve as new technologies are realized. The object-based transaction middleware foundation allows developers to cost-effectively design and implement an adaptive MES utilizing three-tier architecture. This thin system design will allow for continued expansion of the MES along such industry movements and pressures as e-commerce and supply chain management. The evolution of MES will continue to bring greater and greater efficiencies and quality to the manufacturing plant floor, while drastically reducing the total cost of ownership.

Back to top

About the authors

Jim Ricker is Director of Manufacturing Execution Systems for Hampton Tiley Associates, Inc. in Knoxville, TN.

Don Den Uyl II is Technical Manager for Hampton-Tiley Associates, Inc. in Knoxville, TN.

This article is provided courtesy of the ISA - the Instrumentation, Systems, and Automation Society.